Aluminum wiring was used from 1965 until 1972 in some homes in our area due to a severe shortage of copper. Initially considered a safe and economical substitute for copper wire, aluminum was used throughout the country. The aluminum wire used at the time soon developed problems. Its use was discontinued in residential branch wiring for 15 and 20 amp circuits in 1972.

The Southwire Company improved the properties of aluminum wire, and it is currently used in modern aircraft and industrial applications. Aluminum wire is used almost exclusively for utility company transmission lines and service entry wires.

Only single-strand Aluminum wiring is considered unsafe under normal conditions. Stranded aluminum is used in wire sizes eight and larger in residential applications. Due to the bad experiences of the earlier period, solid strand aluminum branch wiring is seldom found in residential construction after 1972.

Aluminum wiring from 1965 to 1972

Our concern is focused on residential wiring installed from 1965 to as late as 1975. Numerous reports of solid strand aluminum wiring overheating and causing fires have been reported. The problem appears to be aluminum’s tendency to expand and contract with different current loads.

The problem is found in receptacles, switches, and light fixtures. As a result, the Consumer Product Safety Commission (CPSC) investigated and recommended a qualified electrician evaluate all aluminum single strand circuits.

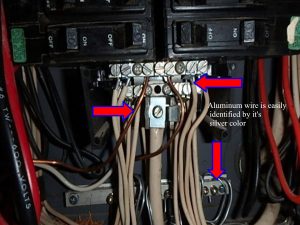

The picture below shows the difference between aluminum and copper wire. The

aluminum wire will appear soft and silver-colored, while the copper wire will be brownish red (copper-colored). Aluminum wire will be marked aluminum on the outer jacket.

In the late 1940s and 50s, some copper wire was “tinned” to prevent corrosion. This wire will usually have a woven cloth-like outer jacket and is not aluminum. This may cause confusion, and a qualified electrician can quickly verify if it is aluminum or copper.

What if My House Has Aluminum Wiring

The fact that your home contains aluminum wiring does not necessarily indicate an immediate problem. However, the US Consumer Product Safety Commission (CPSC) reports:

“A national survey conducted by Franklin Research Institute for CPSC showed that homes built before `1972 (‘old technology aluminum wire’) are 55 times more likely to have one or more wire connections reach “Fire Hazard Conditions ” than is a home wired with copper.” https://www.cpsc.gov//PageFiles/118856/516.pdf

Consumer Product Safety Council Recommendations

The CPSC recommends using a properly trained licensed electrician to inspect and repair residential aluminum wiring. There are many opinions on the proper way to correct aluminum wiring problems; here is what the CPSC recommends:

- Complete Replacement with Copper Cable. Replacement of the aluminum branch circuit conductors with copper wire eliminates the primary cause of the potential hazards, the aluminum wire itself.

2. COPALUM Method of Repair. As an Alternate to rewiring with copper, CPSC recommends attaching a short section of copper wire to the ends of the aluminum wire at connection points (a technique commonly referred to as “pig tailing”), using a special connector named COPALUM to join the wires. CPSC staff considers pig tailing with a COPALUM connector to be a safe and permanent repair of the existing aluminum wiring.

3. Acceptable Alternative Repair Method. CPSC staff recognizes that copper replacement may be cost-prohibitive, and the COPALUM repair may be unavailable in a locality. Based upon an evaluation supported by the CPSC, the AlumiConn connector may be considered the next best alternative for a permanent repair. If the COPALUM repair is not available,

The CPSC continues to explain these are the only methods they approve for repairs. The use of twist-on wire nuts or hardware store-style crimp connectors is not recommended. Only a qualified electrician should attempt aluminum wire repairs.

Caution

Most of all, it is important to remember safety is always our most important goal. Aluminum wire repair is not a “Home Owner” or “Handyman” repair, and experienced and qualified electricians should perform aluminum wiring repair with special tools and training.

Suppose you do have aluminum wire; new receptacles and switches rated for use with copper and aluminum wiring are available. In that case, You should employ a qualified electrician to make these changes.

Hawley Home Inspections LLC is a Veteran owned and family-operated company. We have been serving the St Louis metro area and Southern Illinois since 2010.